The agreement covers all of Hexagon's point cloud processing needs on ROMER "ScanShark" laser probe equipped portable measuring arms, plus Leica Laser Trackers and Leica T-Scan 3D digitizer systems. Under this agreement, Hexagon Metrology will bundle PolyWorks(r) software with industrial measuring systems from four of its core brands: ROMER, Leica Geosystems, DEA and Brown & Sharpe sold in North America. (North Kingstown, RI) have signed an agreement for the distribution of the PolyWorks(r) universal 3D metrology software platform from InnovMetric. (Quebec City, Canada) and Hexagon Metrology, Inc. Starting with 2014 IR11, PolyWorks will no longer support these operating systems.NORTH KINGSTOWN, R.I., (PRIME NEWSWIRE) - InnovMetric Software Inc. With so many clients waiting for these significant improvements, Innovmetric followed suit and ended support for these operating systems.Īs a result, PolyWorks 2014 IR10 will be the last 2014 intermediate release that supports Windows XP and Windows Vista. Unfortunately, Innovmetric needs to integrate release 25 of Spatial’s InterOp CAD translator technology, which solves several issues with CATIA v5 models, successfully imports UG NX V9 models, and will support the most recent versions of other CAD formats, but it does not support Windows XP and Vista. At that time, Innovmetric committed to support these operating systems in PolyWorks 2014 and all its intermediate releases.

In March 2014, InnovMetric announced that Windows XP and Windows Vista would no longer be supported in PolyWorks 2015. The modeling and reverse-engineering solution that enables true interoperability between digitized polygonal models and CAD/CAM applications.

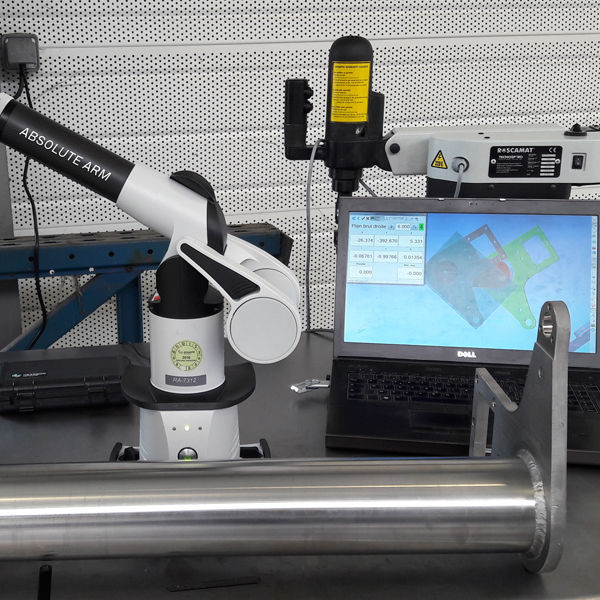

The industry-standard 3D metrology toolbox for product engineering, assembly guidance, and final inspection. It also supports a wide array of native point cloud and polygonal model file formats.įlexible and customizable: With a user interface that can be fully personalized in combination with a powerful, user-friendly macroprogramming language, PolyWorks allows users to successfully develop and deploy automatic inspection processes or guided operator-driven workflows for effective shop floor operations. The PolyWorks software suite maximizes productivity, quality, and profit when integrating 3D measurement technologies into an industrial manufacturing process-covering the complete product development cycle, from part and tool design and prototyping down to final inspection of assembled products.Īs a universal platform, PolyWorks software interfaces directly with major brands and technologies of single-point and point cloud 3D measurement devices through plug-in extension modules.

0 kommentar(er)

0 kommentar(er)